Design

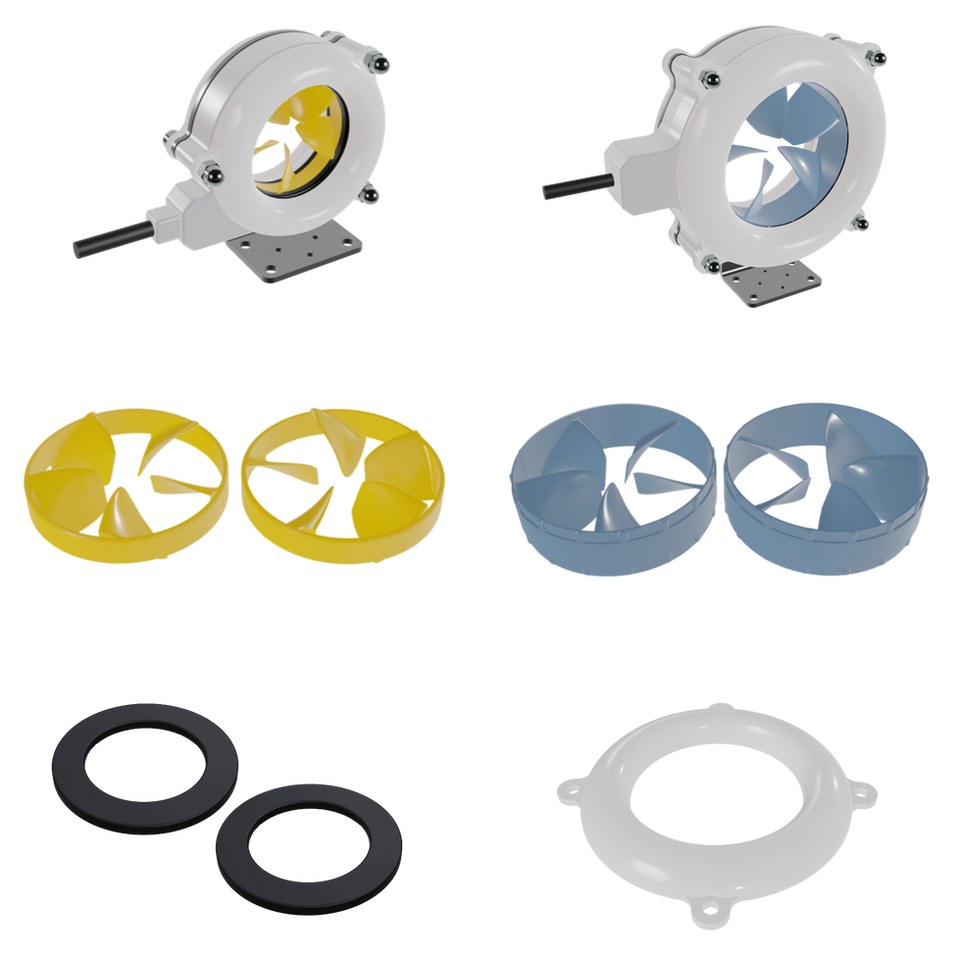

DISKDRIVE™ thrusters are ultra-slim, rim-driven, and brushless, designed for efficient vertical stabilization of underwater vehicles by reducing drag. their hubless propeller prevents robots from getting tangled in debris like plants or ropes. The patented, pressure-proof, oil-free design has no seals, allowing for quick propeller swaps in under 10 seconds without special tools.

ADVANCING YOUR VEHICLE TO THE FUTURE

DISKDRIVE

Operation

DISKDRIVE™ thrusters are user-friendly and compatible with various electronic speed controllers (ESCs). Their symmetrical design delivers equal thrust in both directions, enabling rapid directional changes. For even greater efficiency, the thrusters can be integrated into the vehicle’s hull or paired with optional water flow guiding ducts and a mounting bracket, both available in our webshop.

Ultimate Endurance

Thanks to its unique hydro-lubricated construction, DISKDRIVE™ thrusters are built for exceptional durability. In endurance tests, the DISKDRIVE™ 50 thruster ran continuously for over 7,000 hours and completed 1.2 million directional reversals within 1,000 hours, showing minimal wear.

FEATURES

All You Need

and Even More

Direct-drive

Hubless propeller

Low-profile design

Ultra-compact

Oil-free

Pressure-proof

PRODUCTS

Power and Control

for Your Vehicle

VIDEOS

Watch and Discover

the Depths of DISKDRIVE™

FAQ

The propeller can be easily replaced without tools within a few seconds. By pushing against the blades very close to where they are attached to the ring, the two magnet rings can be pushed apart. The propeller can then be replaced. Just pay attention to the direction of the propeller - a clockwise propeller must be replaced with a clockwise propeller and vice versa.

Detailed instructions with pictures for a propeller change can also be found in the manuals, which you can find in the Technical Documents section of the webpage.

DISKDRIVE™ thrusters are designed exclusively for liquid environments (water or other non-viscous liquids) as they rely on a liquid film forming as lubrication. We do not support the use of our thrusters in air.

Ferromagnetic particles are often found in sand but also in workshop environments. They can accumulate on the magnet rings of the thrusters and end up encrusted in the stator. To remove them, you can use a soft brush to dislodge the loose particles gently or use compressed air to push them away.

In a vehicle, a single propeller generates rotational torque that can cause the vehicle to spin in the opposite direction. By pairing a CW propeller with a CCW propeller, the opposing torques cancel each other out, ensuring stable and controlled operation.

We strongly advise against operating the thruster at a voltage higher than the ones we recommend. Doing so can lead to excessive heat generation, damage the motor windings and lead to potential failure of the thruster. If you require higher voltage configurations, please contact us to discuss potential solutions or alternative models designed for your voltage requirements.

Yes, the thruster is designed to operate in saltwater environments. However, if ferromagnetic particles accumulate on the magnet rings, some corrosion may form on the stator if the thruster remains idle for an extended period. This is easy to address—simply rinse the thruster thoroughly with fresh water after use to wash away any corrosion or debris.